As a parent, we know you don’t wake up wanting bike specs and torque settings—you want a bike that feels effortless and keeps kids coming back to ride. A bike your child can lift, start, balance and stop with confidence. That’s the outcome we design for at base bikes, and it starts long before a box lands at your door. We recently took a trip to see our manufacturing partner, and we'd love to share some snippets of the trip.

The problem most families face

Many kids’ bikes are heavy, sized for adults, or built without the checks that make learning feel natural. The result? Wobbles, frustration, and a bike that gathers dust. For us, that's a tragedy.

Our role

We obsess over weight, balance and kid-sized controls, then partner with a factory that can repeat those details perfectly—every frame, every wheel, every build. We truly believe in quality and do not like poor quality and cheap toys.

Why manufacture in China (for now)?

We’d love to assemble onshore in Australia. Today, the numbers don’t add up without compromising what matters most—light weight, precise tolerances and accessible pricing. Our current partner is the same one used by well-known global brands, with the capacity and discipline to meet our standards batch after batch.

What we looked for on this visit (and every visit)

-

Paint & protection: even coatings for durability; clean interior surfaces where cables and seat posts need to move freely.

-

Wheel builds: consistent spoke tension, true rims and smooth-running hubs.

-

Brakes: kid-sized levers and predictable stopping power; clean cable routing and alignment; correct pads alignment.

-

Assembly checks: torque settings, fastener security, chain tension, handlebar component alignment, quality components used, and no sharp edges where little hands go.

-

Fit & feel: lightweight components, low standover, stable geometry—so the first push feels natural.

Independent testing & safety

Each production run is checked against the relevant Australian standards by independent labs, and we maintain traceability for frames and components.

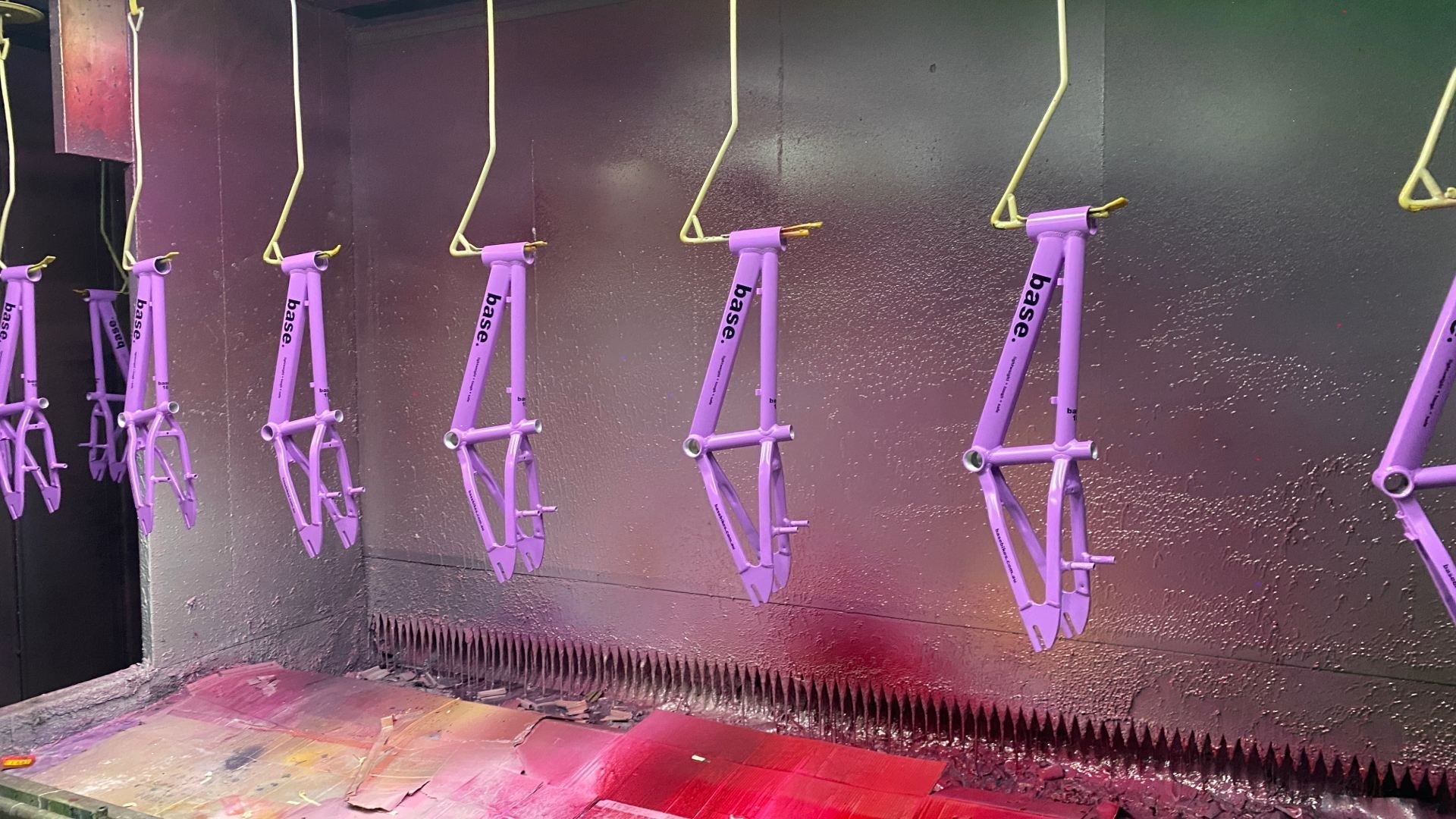

A quick peek from the floor

On the paint line we watched our matte frames getting their finish; in wheel assembly, rims and tyres were racked and checked; on the line, well drilled teams followed precise assembly requirements, specific to our specific requirements. It’s meticulous and even tedious, and that’s the point: consistency is what turns a spec sheet into a better first, second, and hundredth ride.

Looking ahead

We’ll keep sharing these behind-the-scenes updates. Our goal is simple: deliver a bike that helps your child love riding from day one—and keep loving it as they grow.

Are you Ready?

Ready to find your child’s size? Explore base bikes.